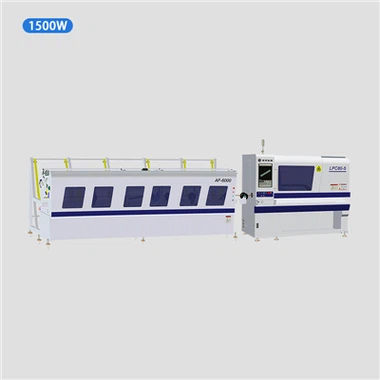

Anji Qingyun Intelligent Equipment Co., Ltd. : Your Trustworthy Laser Pipe Cutting Machine Manufacturer!

Our company was established in 2009. Over the years, the series of automation equipment manufactured by „Anji Jinke” as the brand has been widely used in various types of vehicle accessories, hardware furniture, school tools, bathroom industry, pipeline valves, outdoor products, building heating and many other fields.

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

Rich Product Variety

Advanced Production Equipment

Wide Range of Product Uses

Leading Service

What is Laser Pipe Cutting Machine !

Features Of Laser Pipe Cutting Machine

Precision

Efficiency

Versatility

Minimal Material Waste

Parts Of Laser Pipe Cutting Machine

Laser Cutter Frame

The mechanical part of the laser cutter is responsible for the movement in the X, Y, and Z-axes, including the cutting work platform. The stability of the machine tool is crucial for fiber laser cutting machines, as it directly impacts the cutting precision. Each type of machine tool has its own functions, such as beam type machine tools being mainly used by large manufacturers for material cutting, and 3D fiber laser cutting being mainly used in the automotive industry.

Laser Generator

A device that produces a laser light source is known as a laser generator. The laser generator is the main power source of laser equipment, similar to the engine in a car and is the most expensive component of fiber laser cutting machines.

Lenses

The laser lens is the most commonly used component in fiber laser cutting equipment. Various optical devices contain laser lenses, each serving a different purpose, such as full-reflection lenses, semi-reflection lenses, and focusing lenses.

CNC System

The control system is the primary operating system of the fiber laser cutting machine, which mainly controls the movements of the X, Y, and Z axes and regulates the output power of the laser. Its quality determines the stability of the machine’s operating performance. The precision and cutting effect can be effectively improved through accurate control of the software.

Regulated Power Supply

The connection between the laser generator, the laser cutter, and the power supply system serves mainly to prevent interference from the external power network.

Laser Cutting Head

The cutting head is the laser output device of a fiber laser cutting machine, consisting of a nozzle, a focusing lens, and a focus tracking system. The cutting head drive device, which consists of a servo motor, screw rod, or gear, moves the cutting head along the Z-axis as programmed.

Motor

The motor of the laser cutting machine is a crucial component of the motion system. The performance of the motor directly impacts the processing quality and production efficiency of the product.

How To Use A Laser Pipe Cutting Machine

Machine Setup

This includes loading the desired pipe material onto the machine’s chuck and feeder system. The chuck securely holds the pipe in place, while the feeder allows for continuous processing of multiple pipes.

Calibration and Alignment

The laser head is calibrated to ensure precise positioning and focus of the beam. Additionally, the machine might perform checks for pipe imperfections like bowing, which might require adjustments in the cutting path.

Design Programming

Cutting Process

Part Unloading

Types Of Laser Pipe Cutting Machine

Fiber Laser Pipe Cutting Machine

This type of machine uses a fiber laser source to cut pipes. It is known for its high speed and precision, making it suitable for cutting thin and thick pipes with ease. Fiber lasers can also cut through various materials, including stainless steel, carbon steel, aluminum, and copper.

Hybrid Laser Pipe Cutting Machine

A hybrid laser pipe cutting machine combines both fiber and CO2 laser sources. This type of machine provides the benefits of both fiber and CO2 lasers, allowing it to cut through a wider range of materials and thicknesses. Hybrid laser machines are suitable for high-volume production environments where versatility and efficiency are crucial.

CO2 Laser Pipe Cutting Machine

A CO2 laser pipe cutting machine uses a CO2 laser as the cutting source. It is ideal for cutting thicker pipes made from materials like carbon steel, stainless steel, and mild steel. The CO2 laser produces a higher power output than a fiber laser, which allows it to cut through thicker materials more efficiently.

Slab Laser Pipe Cutting Machine

This type of machine uses a slab laser source to cut pipes. Slab lasers are known for their high power output and ability to cut through thicker pipes. They are typically used in heavy-duty industrial applications where high productivity and durability are required.

How To Choose Laser Pipe Cutting Machine

Pipe Size and Material Compatibility

Cutting Speed and Accuracy

Automation Features

Ease of Use and Operator Training

Maintenance Requirements

Considerations For Thick Pipe Cutting

01/Laser Power

For thicker pipes, a higher laser power is necessary to penetrate the material and achieve clean cuts. Most laser pipe cutting machines for thick pipes typically range from 3kW to 6kW in power.

Cutting thicker pipes generally takes longer than thinner pipes due to the increased material thickness. While fiber lasers offer faster cutting speeds compared to CO2 lasers, the overall cutting time for thick pipes will still be slower.

The type of material being cut can also influence the cutting process. Some materials, such as high-strength steels, may require higher laser power or slower cutting speeds to achieve optimal results.

As the laser beam interacts with the thicker material, the forces exerted on the pipe and the machine increase. A robust and stable machine is essential to maintain precision and prevent vibrations that could affect cut quality.

How To Maintain Laser Pipe Cutting Machine

Regular Maintenance

Perform routine maintenance tasks such as cleaning the machine, inspecting and replacing worn parts, and lubricating moving components. Regular maintenance helps prolong the machine’s lifespan and ensures consistent performance.

Operator Training

Ensure that operators are properly trained in using the laser pipe cutting machine. They should be familiar with safety protocols, machine operation, and troubleshooting procedures.

Protective Gear

Operators should wear appropriate protective gear, including safety glasses, gloves, and ear protection. This protects them from potential hazards such as laser radiation, sparks, and noise.

Our Certificate

Applications of Laser Pipe Cutting Machine

Furniture Manufacturing

Cutting intricate designs and components for furniture frames, railings, and decorative elements.

Construction

Laser pipe cutting machines are used in construction to fabricate structural components such as handrails, staircases, and support beams. The precision of laser cutting ensures that these elements fit together seamlessly.Creating customized pipe supports, brackets, and HVAC ductwork.

Automotive Industry

The automotive industry relies on laser pipe cutting machines for fabricating exhaust systems, chassis components, and roll cages. The ability to create complex shapes and contours makes laser cutting ideal for these applications.Fabricating exhaust pipes, roll cages, and other tubular components for vehicles.

Aerospace

In aerospace manufacturing, precision is crucial for components such as turbine blades and exhaust systems. Laser pipe cutting machines offer the accuracy and consistency required for these critical applications.

Plumbing

In plumbing, laser pipe cutting machines are used to create precise cuts for pipes and fittings. This ensures leak-free connections and efficient plumbing systems.

Applications of Laser Pipe Cutting Machine

Q: What is a laser pipe cutting machine?

A: A laser pipe cutting machine is an advanced manufacturing tool that uses a high-powered laser beam to cut through metal pipes with precision and speed. It’s widely used in industries where accurate and efficient pipe cutting is required.

Q: How does a laser pipe cutting machine work?

A: The machine directs a high-power laser beam onto the surface of the pipe. The heat generated by the laser melts or vaporizes the material, allowing the cutting head to move along the pre-programmed path and create precise cuts.

Q: What are the advantages of using a laser pipe cutting machine over traditional methods?A: Laser cutting offers several advantages over traditional methods, including faster cutting speeds, higher precision, reduced material waste, and lower labor costs. It also allows for complex shapes and designs to be cut quickly and easily.

Q: What types of materials can a laser pipe cutting machine cut?

A: Laser cutting machines can cut a wide variety of materials, including carbon steel, stainless steel, aluminum, copper, brass, and even some plastics. The type of material will determine the power and wavelength of the laser needed.

Q: How thick can a laser pipe cutting machine cut?

A: The thickness of material that a laser pipe cutting machine can cut depends on the power of the laser and the type of material being cut. Generally, fiber lasers can cut up to 20mm thick material, while CO2 lasers can cut up to 30mm thick material.

Q: Is laser pipe cutting machine suitable for all sizes of pipes?

A: Yes, laser pipe cutting machines are designed to accommodate pipes of various diameters and lengths. Some machines are capable of cutting pipes with diameters ranging from a few millimeters to several meters.

Q: How accurate are laser pipe cutting machines?

A: Laser pipe cutting machines are highly accurate, with tolerances typically in the range of ±0.1mm. This level of accuracy ensures that parts fit together perfectly, reducing the need for rework or scrap.

Q: What factors affect the cutting speed of a laser pipe cutting machine?

A: Several factors can affect the cutting speed of a laser pipe cutting machine, including the power of the laser, the material being cut, the thickness of the material, and the complexity of the design. Generally, thicker materials and more complex designs require slower cutting speeds.

Q: Can a laser pipe cutting machine be used outdoors?

A: While some laser pipe cutting machines are designed for outdoor use, most are best suited for indoor environments. This is because the laser beam can be affected by environmental factors such as wind, rain, and humidity, which can reduce its cutting performance.

Q: How much maintenance does a laser pipe cutting machine require?

A: Laser pipe cutting machines require regular maintenance to ensure optimal performance. This includes cleaning and aligning the optics, replacing consumables such as lenses and nozzles, and checking and tightening all mechanical components. The frequency of maintenance will depend on the intensity of use and the operating environment.

Q: Are there any safety precautions I should take when using a laser pipe cutting machine?

A: Yes, there are several safety precautions you should take when using a laser pipe cutting machine. These include wearing appropriate protective clothing and eyewear, ensuring that the work area is well-ventilated, and keeping flammable materials away from the laser beam. You should also follow the manufacturer’s guidelines for safe operation and maintenance.

Q: How much does a laser pipe cutting machine cost?

A: The cost of a laser pipe cutting machine can vary depending on its size, power, features, and brand. Generally, prices range from tens of thousands to hundreds of thousands of dollars. It’s important to consider not only the initial purchase price but also the ongoing costs of maintenance and consumables.

Q: What is the lifespan of a laser pipe cutting machine?

A: The lifespan of a laser pipe cutting machine depends on several factors, including the quality of the machine, the intensity of use, and the level of maintenance provided. Generally, a well-maintained machine can last for many years, often exceeding 10,000 hours of operation.

Q: Can I customize a laser pipe cutting machine?

A: Many manufacturers offer customization options for their laser pipe cutting machines. This can include adding additional axes for increased flexibility, integrating automation systems for increased productivity, or upgrading to more powerful lasers for cutting thicker materials.

Q: How easy is it to operate a laser pipe cutting machine?

A: Operating a laser pipe cutting machine requires some training and experience. However, most machines come with user-friendly software thatmakes it relatively easy to set up and run jobs. Manufacturers also provide comprehensive training and support to help operators get up to speed quickly.

Q: What are the limitations of laser pipe cutting machines?

A: While laser pipe cutting machines offer many advantages, they do have some limitations. These include the inability to cut through very thick materials (more than 30mm for CO2 lasers) or extremely reflective surfaces (such as polished stainless steel).

Q: How fast can a laser pipe cutting machine cut?

A: The cutting speed of a laser pipe cutting machine varies depending on the factors mentioned earlier (power, material type, thickness, and design complexity). Generally, fiber lasers are faster than CO2 lasers due to their higher cutting speeds and efficiency. Some machines can achieve cutting speeds of several meters per minute for thin materials.

Q: Can a laser pipe cutting machine be integrated into existing production lines?

A: Yes, many laser pipe cutting machines can be integrated into existing production lines to improve efficiency and flexibility. This can involve automating the loading and unloading of pipes, integrating with CAD/CAM software for seamless job management, and connecting to other automated systems within the factory.

Q: How do I choose the right laser pipe cutting machine for my needs?

A: Choosing the right laser pipe cutting machine depends on several factors, including your budget, the types of materials and thicknesses you need to cut, your desired cutting speed and accuracy, and any additional features or customizations you might require. It’s also important to consider the reputation and after-sales support of the manufacturer.

Q: What is the difference between a fiber laser and a CO2 laser in terms of pipe cutting?

A: Fiber lasers and CO2 lasers are two different types of laser technologies used for pipe cutting. Fiber lasers are generally faster, more efficient, and require less maintenance than CO2 lasers. They are also better suited for cutting thinner materials and can achieve higher precision cuts. On the other hand, CO2 lasers are better suited for cutting thicker materials and are capable of handling a wider range of material types.

Q: How does the size of the pipe affect the cutting process?

A: The size of the pipe can affect the cutting process in several ways. Larger pipes may require more powerful lasers and longer focal lengths to ensure adequate coverage and penetration. Additionally, larger pipes may be more difficult to handle and position accurately, which can impact the cutting speed and accuracy. Specialized machines or fixtures may be required to hold and guide larger pipes during the cutting process.

Q: What is the role of software in laser pipe cutting?

A: Software plays a critical role in laser pipe cutting by enabling users to design and program complex cutting patterns with ease. Most machines come with dedicated software that allows for the importation of CAD files, the creation of custom shapes and designs, and the optimization of cutting paths to minimize material waste and maximize productivity. Advanced software features can also include simulations of the cutting process, real-time monitoring of machine parameters, and integration with other manufacturing systems.

Q: How does the environment affect laser pipe cutting?

A: The environment can have a significant impact on the performance and longevity of a laser pipe cutting machine. Factors such as temperature, humidity, dust, and vibrations can all affect the stability and alignment of the machine’s optical components, leading to reduced cutting quality and increased maintenance requirements. To mitigate these effects, it’s important to maintain a stable and clean operating environment and follow the manufacturer’s recommendations for ventilation and cooling.

As one of the leading laser pipe cutting machine manufacturers in China, we warmly welcome you to buy durable laser pipe cutting machine for sale here from our factory. All machines are with high quality and competitive price.