Tube Laser Machine

999999,00 zł

Do You Have Questions? Call Us +1 255 854 55 26

Description

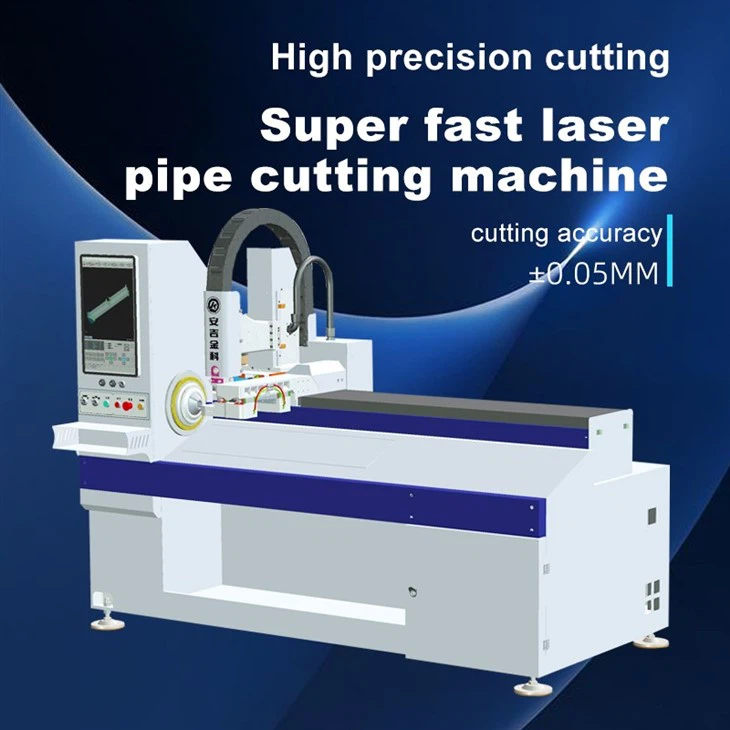

Product Introduction

LPC80-B5-DF6000-2000w Tube laser machine Wide range operation, suitable for a variety of pipe cutting, suitable for long pipe cutting, porous through the hole, high precision requirements of the pipe. Independently developed bus control system, professional and efficient, stable system, simple operation. Servo pull, reduce pull times, full stroke cutting, improve efficiency.

Product Parameter

| Mode | LPC80-B5 Tube laser machine |

| Length of pipe | Unlimited length |

| Diameter of pipe | φ6-φ80 |

| Tail | ≥50MM |

| Cutting precision | ±0.05MM |

| Position precision | ±0.1MM (Accuracy of pipe itself with±0.1) |

| Total weight | 950kg |

| Dimension | 2350mm×1300mm×2300mm |

| Major Parameter | Five-axis automatic rack DF-6000 |

| loading mode | Belt lifting type |

| Packing weight | 1.5T |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ13-φ110 |

| Length of pipe in use | 5000-7000MM |

| power supply requirement | 220V/50HZ |

| external dimension | 5520*1780*1730 |

Product Feature And Application

Product Feature:

(1) Equipped with high-performance servo pulling system and pipe core fastening function.

(2) The use of full stroke cutting technology to reduce the number of drawing in the process.

(3) While improving the cutting speed, ensure that the cutting accuracy of the pipe reaches a higher standard.

This fiber laser cutting head offers excellent cutting accuracy, Fast response speed and excellent optical stability.

Autonomous, Efficient, BUS architecture, Easy to operate.

Fast and accurate fastening response ensures non-destructive tube surfaces.

Efficient Tube laser machine, high precision and can handle shaped or special forms of steel pipe.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

Delivery, Shipping And Serving

1) We can send technical engineers at home and abroad for installation, commissioning and even after-sales service. We also offer free training on how to properly use the manipulator and even the software. Our technical support center is staffed by experienced service professionals. We handle more than 10,000 requests per year and resolve 95% of them with online support alone. Our technical support professionals are available 24 hours a day, 365 days a year.

2) Our service professionals can help you:

Diagnosis and troubleshooting

Evaluate machine performance

Confirmation component

Install and/or remove components

Check software and control systems

Optimize equipment efficiency

3) Machine warranty 1~3 years.

4) At the end of the warranty period, the buyer only pays the cost of the parts and the actual maintenance costs

FAQ