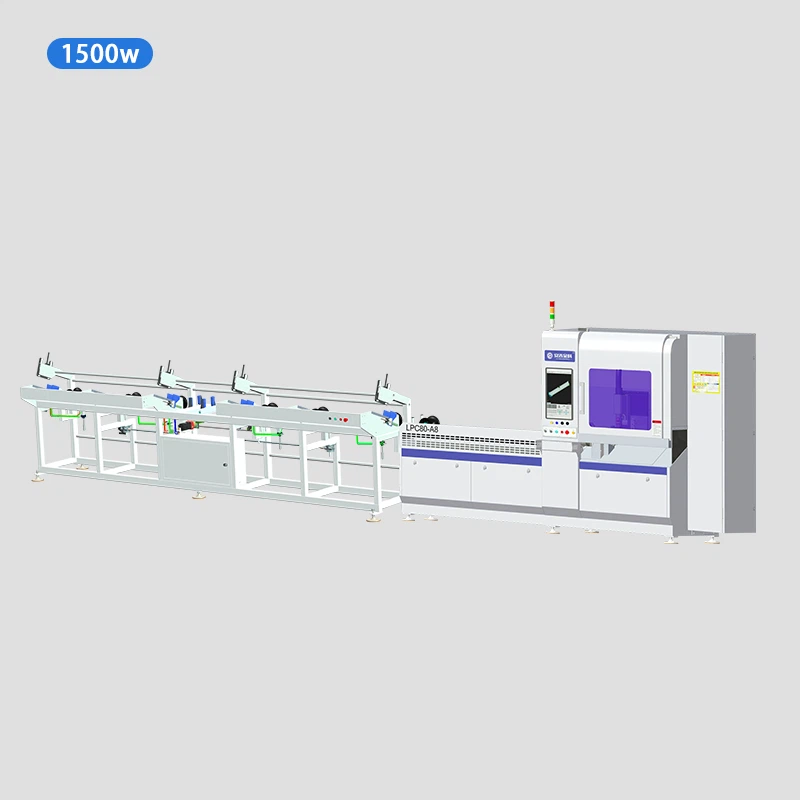

Tube Bevel Fiber Laser Cutting Machine

999999,00 zł

LPC80-A8-CF6000 Tube bevel Fiber Laser Cutting Machine is specially developed for small and medium-sized pipe bevel cutting, with self-developed high-precision concentric swing mechanism and closed high-precision power head, can be cut freely within the range of ±45º bevel, and the product has good sealing. Tube bevel Fiber Laser Cutting Machine not only durable, but also reduce

Do You Have Questions? Call Us +1 255 854 55 26

Description

Product Introduction

LPC80-A8-CF6000 Tube bevel Fiber Laser Cutting Machine is specially developed for small and medium-sized pipe bevel cutting, with self-developed high-precision concentric swing mechanism and closed high-precision power head, can be cut freely within the range of ±45º bevel, and the product has good sealing. Tube bevel Fiber Laser Cutting Machine not only durable, but also reduce maintenance costs. The clamping support of the double chuck greatly improves positioning accuracy and saves more tail material.

Product Parameter

| Mode | LPC80-A8 Tube bevel Fiber Laser Cutting Machine |

| Length of pipe | Unlimited length |

| Diameter of pipe | φ10-φ80 |

| Tail | ≥50MM |

| X axis stroke | 1500MM |

| U-axis swing axis stroke | ±45º |

| Cutting precision | ±0.05MM |

| Position precision | ±0.2MM |

| Accelerated speed | 1.5G |

| Chuck bearing | 80kg |

| Total weight | 2.2T |

| Power Supply | 380V |

| Major Parameter | Semi-automatic rack CF-6000 |

| loading mode | Permutation |

| Tank length | 400MM |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ10-φ110 |

| Length of pipe in use | 5000-7000MM |

| power supply requirement | 220V/50HZ |

| external dimension | 5520*1080*1620 |

Product Feature And Application

Product Feature:

(1) Stronger technology: ±45° bevel cutting, double chuck positioning, high precision.

(2) Wide application: suitable for round pipe, square pipe, shaped pipe, etc.

(3) Excellent cutting quality: high precision cutting, seamless stitching.

Our self-developed bus system is outstanding for its rapid dynamic feedback, efficient signal transmission efficiency, and the pursuit of simplicity in line design to ensure excellent stability. The user interface is intuitive and simple, and the machining path can be displayed instantly in the 3D model, supporting the accurate processing of complex corners. The one-click cutting function further simplifies the operation and, combined with intelligent optimization of the surface processing sequence, significantly reduces unnecessary rotation and greatly increases the speed and efficiency of machining.

With the unique center swing design, the high precision control of the swing is realized, and the accuracy requirement of the nozzle is reduced. Automatic height adjustment is built into the cutting equipment to ensure the fine quality of the cutting surface. The internal structure of the product is designed to optimize the sealing performance and effectively prevent optical components from being contaminated, thus improving the durability of the equipment. The machine supports standard pipe end miter cutting, and the vertical cutting process is flexible and efficient, which can be adapted to cut at any Angle within the ±45 degree bevel range. In addition, the cutting heads used meet industry standards and are suitable for a variety of stereoscopic cutting scenarios, and the commonality of consumables guarantees ease of use and maintainability.

The specially designed high-precision fully enclosed power head greatly limits the infiltration of dust, thus reducing the cost of maintenance.

The use of double chuck clamping method increases the stability, significantly improves the accuracy of positioning, while strengthening the cutting ability of the bevel, effectively saving material allowance. In other words, these improvements mean significant improvements in performance and material savings without changing the original intent., the tail material ≥200MM.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

Delivery, Shipping And Serving

1) We offer lifelong support: Whether it’s a breakdown or regular maintenance, we’re here for you.

2) Flexible payment options: Choose from staged payments or financing.

3) Personalized on-site assistance: Receive one-on-one guidance on using and maintaining the laser pipe cutting machine, as well as creating three-dimensional drawings.

4) One-year comprehensive warranty: We’re committed to resolving any issues to safeguard your investment.

FAQ