High Speed Laser Cutting Machine

999999,00 zł

Do You Have Questions? Call Us +1 255 854 55 26

Description

Product Introduction

LPC80-B5-BF6000 high speed laser cutting machine can achieve high-speed cutting at the same time can maintain high precision cutting, can meet the production needs of many pipe processing manufacturers, loved by customers, semi-automatic feeding equipment makes it more time and labor-saving operation

Product Parameter

| Mode | LPC80-B5 high speed laser cutting machine |

| Length of pipe | Unlimited length |

| Diameter of pipe | φ6-φ80 |

| Tail | ≥50MM |

| Cutting precision | ±0.05MM |

| Position precision | ±0.1MM |

| Total weight | 900kg |

| Dimension | 2350mm×1300mm×1900mm |

| Major Parameter | Semi-automatic rack CF-6000 |

| loading mode | Arranged pulling material |

| Tank length | 400mm |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ10-φ110 |

| Length of pipe in use | 5000-7000MM |

| power supply requirement | 220V/50HZ |

| external dimension | 5520*1080*1620 |

Product Feature And Application

Product Feature:

(1) Equipped with bus control system, servo control, with pipe center clamping function.

(2) Can realize the whole pipe cutting, reduce the time of pulling material, and improve the production speed.

(3) All this parts match well with each other, machine’s stability is great, fast cutting speed and good precision.

The flexible operation is simple, has the function of laser power adjustment, to ensure the quality of cutting, the operation is simple and convenient.

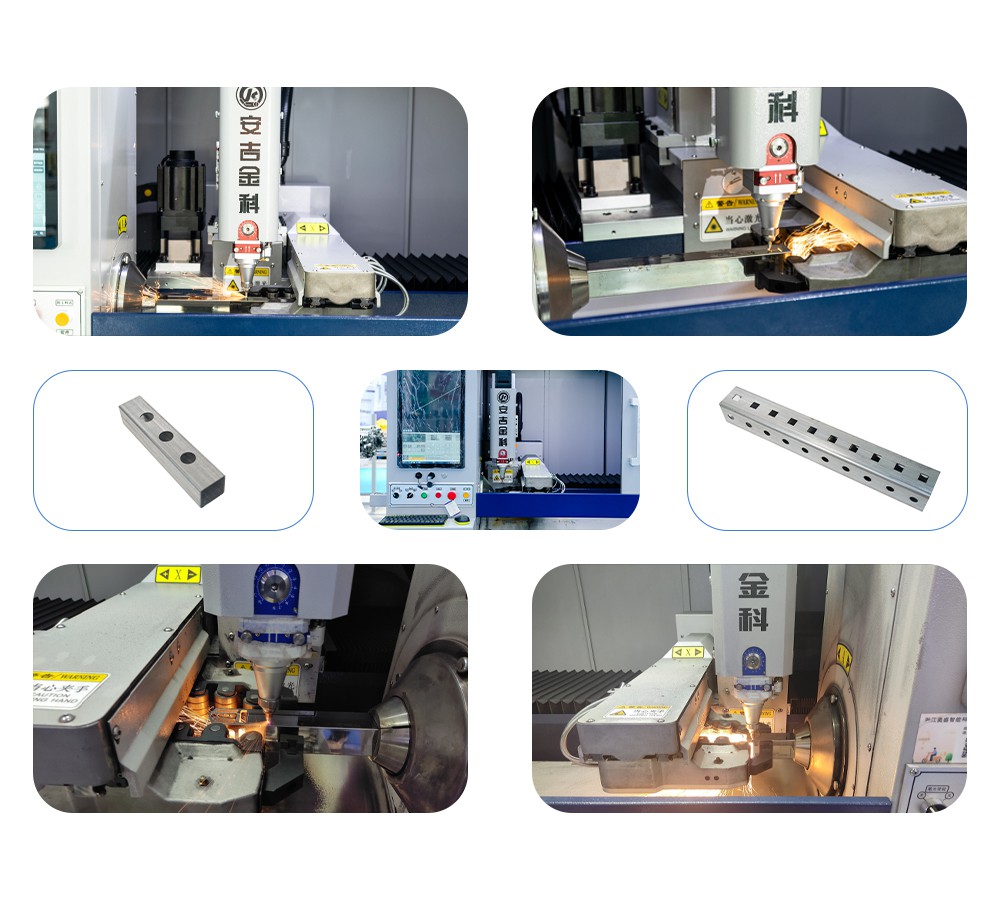

High speed laser cutting machine is inseparable from strong power head, Support fast cutting, High quality cutting, not only can cut conventional pipe, but also cut special-shaped pipe.

Pipe handling is more intelligent and efficient, reducing the number of pulling materials and achieving full stroke cutting

High precision laser cutting head, stable light output, fast response, to ensure the best cutting effect.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

After-Sales Service

1) Lost material: The loss of materials are generally lenses and copper nozzle, you can buy online, you can also contact the after-sales service directly, in our company to buy

2) Payment method: We support a variety of payment methods, installments or financing, so that your payment more convenient.

3) After-sales commissioning: We provide one to three days of after-sales training, and we also provide free drafting and operation training on a regular basis, so we need an employee with a certain ability to learn

4) Warranty period: In order to fully protect your rights and interests, we provide equipment warranty service for one year, when your equipment fails, please contact us immediately.

FAQ