Cnc Laser Tube Cutter

999999,00 zł

Do You Have Questions? Call Us +1 255 854 55 26

Description

Product Introduction

LPC80-A8-DF6000 CNC laser tube cutter is our product designed for the high precision and high efficiency of pipe processing needs, with double chuck clamping, high stability, short remaining material, the cut pipe can be seamless splicing, and the application surface is very wide

Product Parameter

| Mode | LPC80-A8 CNC laser tube cutter |

| Length of pipe | Unlimited length |

| Diameter of pipe | Φ10-φ80 |

| Tail | Groove≥220MM

Straight cut ≥75MM |

| U axis swing axis stroke | ±45° |

| Cutting precision | ±0.03MM |

| Position precision | ±0.1MM |

| Slot width | 0.1-0.2MM |

| Accelerated speed | 1.5G |

| Pulling way | Air-operated |

| Total weight | 2.2T |

| Power Supply | 380V |

| Dimension | 7870mm×1478mm×2100mm |

| Major Parameter | Manual operation DF-6000 |

| loading mode | Manual operation |

| Packing weight | 1T |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ6-φ110 |

| Length of pipe in use | Unlimited length |

| external dimension | 5900*1300*1730 |

Product Feature And Application

Product Feature:

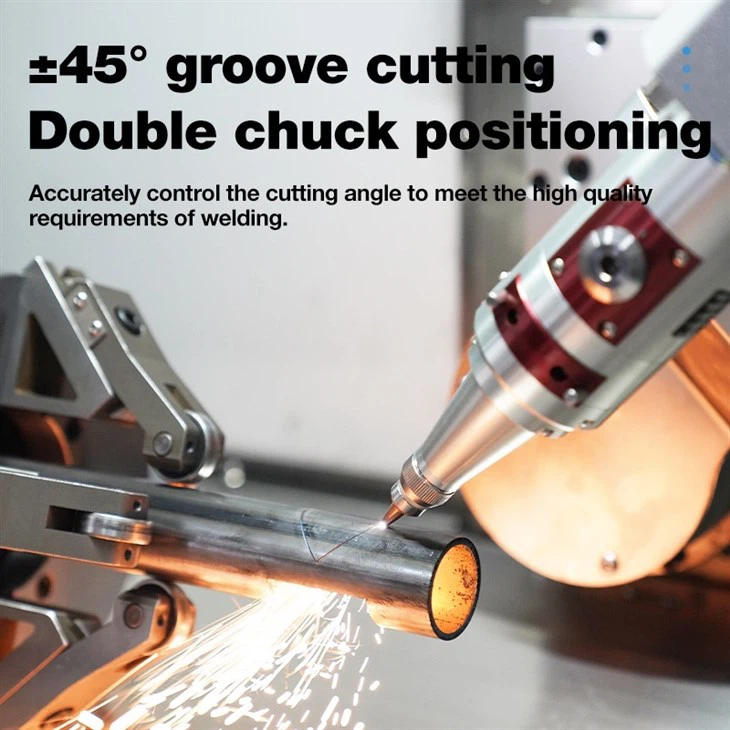

(1) Precision ±45° bevel cutting

(2) Superior precision, seamless splicing

(3) Endeavor in self-developed software system, facilitating operation

Enhanced Technology

±45° bevel cutting, dual chuck positioning, superior accuracy.

Extensive Application Range

A comprehensive CNC laser tube cutter designed for applications on round, square, shaped pipes, etc.

Self-developed Bus System

Prominent dynamic response, elevated signal transmission efficiency, streamlined line, steady stability, user-friendly operation, endorsing corner process, curbing the number of rotations, significantly enhancing processing efficiency.

Original High-precision Groove Swing Mechanism

The innovative concentric swing design enhances the swing accuracy, and the integrated automatic height adjustment guarantees a pristine cutting surface.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

Delivery, Shipping Ad Serving

1) Free upgrade:We sell products system upgrades are free of charge, do not need to pay additional costs

2) After-sales commissioning:It is generally one to three days, until learning, the company regularly provides free drafting and operation training

3) Consumable consumption:Lenses and copper nozzle are the biggest consumption, very cheap.

4) Delivery cycle: It is generally about 10 days, including automatic feeding equipment to about 15 days, sometimes there will be stock.

FAQ