Bevel Laser Tube Cutting Machine

999999,00 zł

Do You Have Questions? Call Us +1 255 854 55 26

Description

Product Introduction

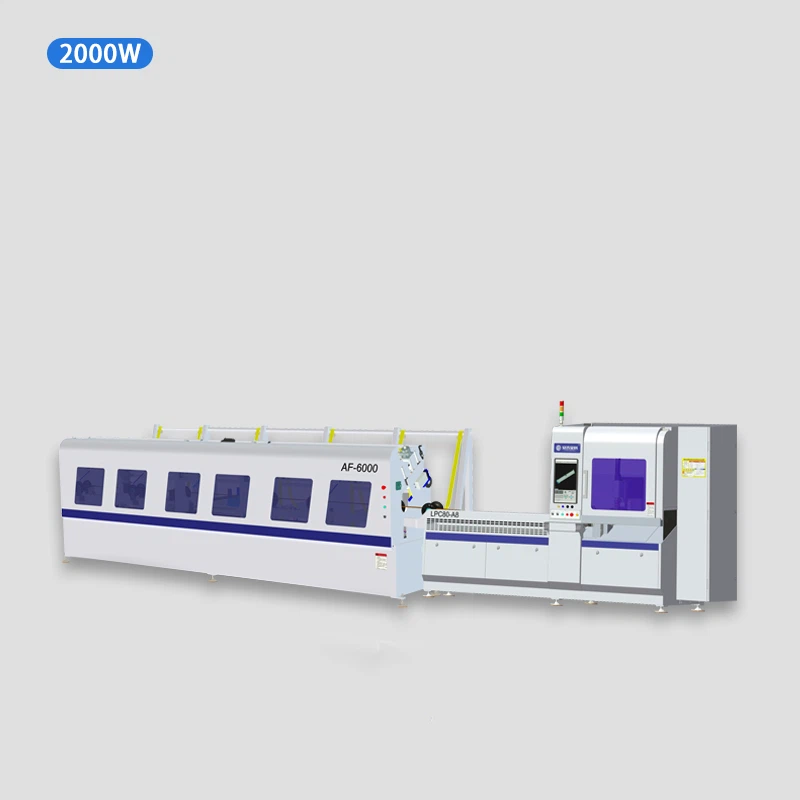

LPC80-A8-AF6000 bevel laser tube cutting machine is suitable for cutting a variety of pipe types, ±45 degree bevel cutting makes the quality better, the splicing is simpler, the self-developed bus control system, the response speed is fast, the equipment stability is higher.

Product Parameter

| Mode | LPC80-A8 bevel laser tube cutting machine |

| Length of pipe | Unlimited length |

| Diameter of pipe | Φ10-φ80 |

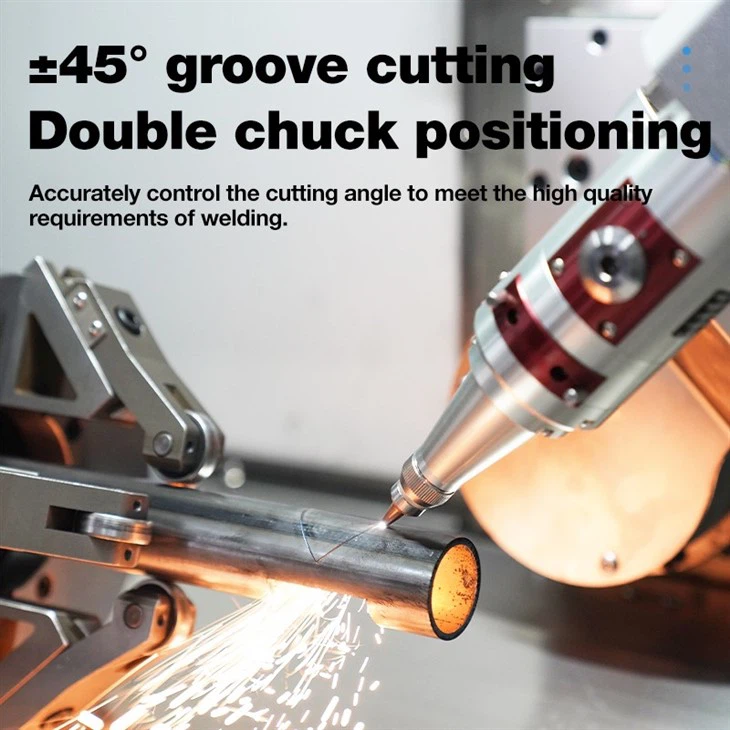

| U-axis swing axis stroke | ±45° |

| Cutting precision | ±0.05MM |

| Position precision | ±0.2MM |

| Slot width | 0.1-0.2MM |

| Repositioning Accuracy | ±0.03MM |

| Maximum accelerated speed | 1.5G |

| Chuck bearing | 80kg |

| Whole machine weight | 2.2T |

| Rated voltage of power Supply | 380V |

| Dimension | 9550mm×1500mm×2380mm |

| Major Parameter | Five-axis automatic rack AF-6000 |

| loading mode | Pull and lift |

| Packing weight | 1.5T |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ13-φ110 |

| Length of pipe in use | 5000-7000MM |

| power supply requirement | 220V/50HZ |

| external dimension | 5520*1780*1730 |

Product Feature And Application

Product Feature:

(1) ±45 Bevel cutting

(2) Many types of tubes can be cut

(3) High cutting accuracy

It is simpler and more convenient to operate, easier to use, and there is a 3D model display, you can see the path of cutting, you can do one-click cutting, greatly improving the production efficiency

The intimal structure of the product has good sealing performance, which can avoid environmental pollution of the optical part and is durable.

Customized version of high precision integrated enclosed power head, it can effectively reduce dust entry, protect equipment, and reduce the risk of damage

The two chucks are clamped to make the pipe more firm when cutting and the bevel cutting more accurate, with tailings ≥200MM.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

Delivery, Shipping And Serving

Excellent support in a variety of applications, including:

Equipment operation, care and maintenance Equipment disassembly, recovery and repair installation and operation.

1) Quality assurance: All components are tested and carefully selected. We test all components to ensure they meet quality standards. Our goal is to eliminate faults at their root and ensure that all components are trouble-free. If there is any problem, we will deal with it immediately.

2) Quick response: Provide help quickly when needed. We offer 24-hour telephone support and a service center.

3) Excellent service: If you need help, please feel free to contact us. We have an experienced and trained team ready to serve you.

FAQ