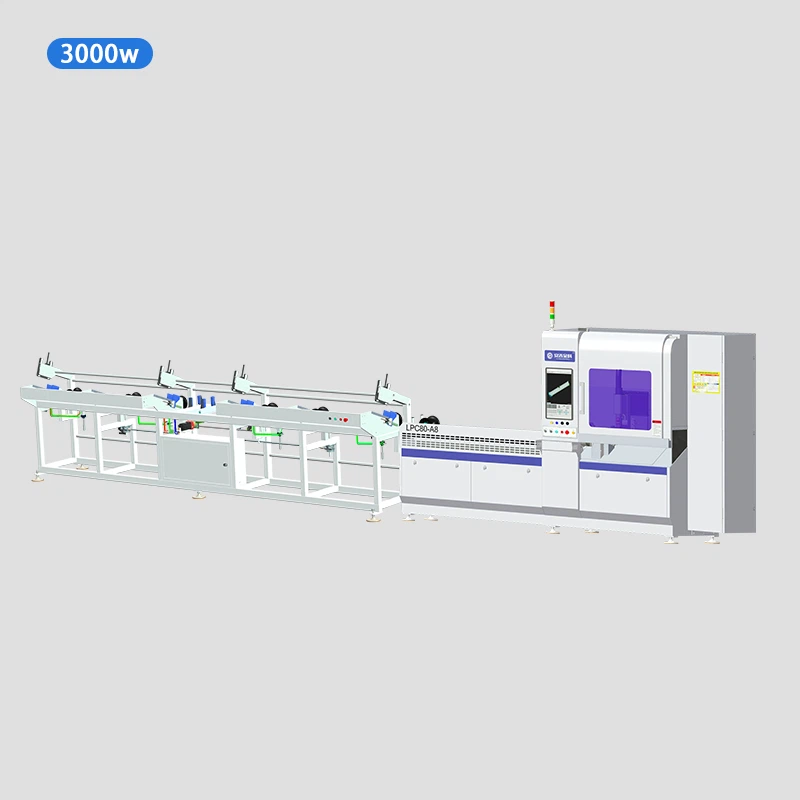

3d Tube Laser Cutting Machine

999999,00 zł

Do You Have Questions? Call Us +1 255 854 55 26

Description

Product Introduction

LPC80-A8-CF6000 is a 3d tube laser cutting machine specially developed for small and medium-sized pipe bevel cutting, which is more powerful than the straight laser pipe cutting machine. It can cut freely within the range of ±45º bevel, not only round tubes, square tubes and rectangular tubes, but also special-shaped tubes. The cutting quality is better, and the high-precision concentric swing mechanism ensures seamless connection at the joint of the pipe. The semi-automatic rack is highly cost-effective and can reduce labor costs.

Product Parameter

| Mode | LPC80-A8 3d tube laser cutting machine |

| Length of pipe | Unlimited length |

| Diameter of pipe | φ10-φ80 |

| Tail | ≥50MM |

| X axis stroke | 1500MM |

| U-axis swing axis stroke | ±45º |

| Cutting precision | ±0.05MM |

| Position precision | ±0.2MM |

| Accelerated speed | 1.5G |

| Chuck bearing | 80kg |

| Total weight | 2.2T |

| Power Supply | 380V |

| Major Parameter | Semi-automatic rack CF-6000 |

| loading mode | Permutation |

| Tank length | 400MM |

| Suitable tube type | Round tube, square tube, rectangular tube |

| Tube feeding range | φ10-φ110 |

| Length of pipe in use | 5000-7000MM |

| power supply requirement | 220V/50HZ |

| external dimension | 5520*1080*1620 |

Product Feature And Application

Product Feature:

(1) It has high precision, such as ±45° miter cutting, installation and positioning is also very convenient and simple, easy to operate.

(2) Widely used, suitable for various specifications and shapes of the pipe, such as round pipe, square pipe, shaped pipe and so on.

(3) Excellent cutting quality: High cutting precision and seamless stitching.

This independently developed bus system has fast dynamic response, high signal transmission efficiency, and simple line, providing a stable operating environment. The system can display the machining path in real time, support one-key fly cutting, prioritize the surface, and reduce the number of rotations, improving processing efficiency.

Original concentric swing design, high precision, consumables versatility, swing design reduces the nozzle requirements. Built-in automatic height adjustment ensures fine cutting surface. Good sealing, avoid pollution, long service life, internal structure standard, oblique cutting, vertical cutting freely change. Standard stereoscopic cutting head is used.

We have customized a highly accurate integrated enclosed power head, which reduces the amount of ash entering the equipment, reduces maintenance costs, and ensures that the equipment can continue to operate for a longer period of time.

This 3D tube laser cutting machine uses a double chuck clamping bracket to improve positioning accuracy and stability, save tailstock and reduce maintenance costs. Customized high precision integrated closed power head reduces ash inlet.

Application Industry:

Production Details

Product Qualification

Strength proves trustworthiness:

Ingenuity manufacturing, strength exhibition:

Our Certificates

Delivery, Shipping And Serving

1) We provide lifelong support, whether it’s for breakdowns or regular maintenance, we are dedicated to assisting you.

2) We offer flexible payment options, including staged payments and financing plans.

3) Personalized on-site assistance is available to guide you in using and maintaining the laser pipe cutting machine, as well as creating three-dimensional drawings.

4) Our one-year comprehensive warranty demonstrates our commitment to resolving any issues and protecting your investment.

FAQ