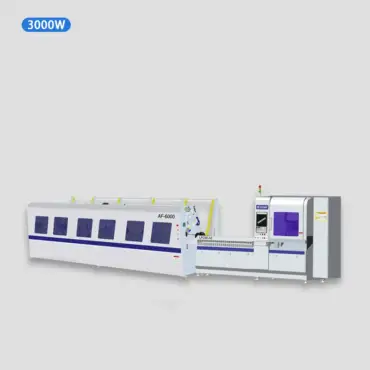

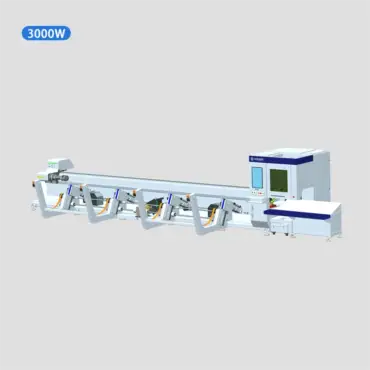

Bevel Laser Pipe Cutting Machine

Our company was established in 2009. Over the years, the series of automation equipment manufactured by „Anji Jinke” as the brand has been widely used in various types of vehicle accessories, hardware furniture, school tools, bathroom industry, pipeline valves, outdoor products, building heating and many other fields.

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

-

999999,00 zł

Rich Product Variety

Advanced Production Equipment

Wide Range of Product Uses

Leading Service

What is Bevel Laser Pipe Cutting Machine

What is Bevel Laser Pipe Cutting Machine A Bevel Laser Pipe Cutting Machine is a high-precision cutting system used to cut pipes with beveled edges. This machine employs a laser as the primary cutting tool, allowing for precise and clean cuts that are essential in various industries, such as oil and gas, construction, and manufacturing.

Features Of Bevel Laser Pipe Cutting Machine

Precision Cutting

The laser beam provides a high degree of accuracy, allowing for tight tolerances in the cut. This results in precise dimensions and angles, which are crucial for welding and assembly processes.

Versatility

These machines can handle different materials such as carbon steel, stainless steel, aluminum, and others. They can also cut a wide range of pipe diameters and wall thicknesses.

Automation

The cutting process is highly automated, reducing the need for manual intervention. This automation includes loading and unloading of pipes, positioning, cutting, and beveling.

CNC Control

Computer Numerical Control (CNC) allows for programmable operation, enabling the user to set up complex cuts and bevels with ease. CNC systems also ensure consistency and repeatability across multiple cuts.

No Tool Wear

Since there is no physical contact between the cutting tool and the workpiece, there is no wear on cutting edges or tools, leading to lower maintenance costs and longer machine life.

Parts Of Bevel Laser Pipe Cutting Machine

Laser Source

The heart of the system, the laser source generates the high-powered beam necessary for cutting. Common types include CO2 lasers and solid-state lasers like fiber lasers.

Cutting Head

This component houses the laser optics and nozzle. It moves along the X and Y axes, directing the laser beam onto the surface of the pipe.

Beam Delivery System

This includes mirrors and lenses that guide the laser beam from the source to the cutting head. The beam delivery system ensures the beam maintains its focus and intensity throughout its path.

Motion Control System

Comprised of servo motors, drives, and controllers, this system enables precise movement of the cutting head and the pipe carriage along the X, Y, and sometimes Z axes.

CNC

The CNC system is the brain of the machine, controlling the motion of the cutting head and the pipe carriage based on the programmed instructions. It coordinates all movements to achieve accurate cuts and bevels.

Pipe Carriage

This part supports the pipe and moves it through the machine during the cutting process. It may have adjustments to accommodate different pipe sizes and shapes.

Vacuum or Blowback System

To keep the cut clean and free of slag, a vacuum system may be used to extract dust and debris, or a blowback system might eject material away from the cut.

Chiller Unit

High-powered lasers generate a lot of heat, so a chiller unit is used to cool the laser medium and other critical components, ensuring stable operation and longevity.

Control Panel

An operator interface that allows users to input programs, adjust settings, monitor machine status, and initiate cuts.

Guarding and Enclosure

Safety features that protect operators from the laser and moving parts, while also containing any flying sparks or debris.

Exhaust and Filtration System

Captures and vents smoke, fumes, and other byproducts generated during the cutting process, and filters them to meet environmental standards.

Pipe Clamping or Fixturing System

Secures the pipe in place during cutting to prevent movement and ensure precision.

How To Choose Bevel Laser Pipe Cutting Machine

Cutting Materials

Verify that the machine can handle the type and thickness of material you want to cut.

Cutting Capacity And Speed

Evaluate the machine’s ability to meet your production needs in terms of speed and volume.

Accuracy

Ensure the machine delivers the level of accuracy required for your project, especially complex designs.

Ease Of Operation

The software and controls should be user-friendly and integrate seamlessly into your operation.

Working Principle Of Bevel Laser Pipe Cutting Machine

PROGRAMMING

CUTTING PROCESS

BEVELING

QUALITY CONTROL

PIPE POSITIONING

LASER ACTIVATION

HEAT MANAGEMENT

DEBRIS REMOVAL

How To Maintain Bevel Laser Pipe Cutting Machine

Regularly Clean The Bevel Laser Pipe Cutting Machine

A clean Bevel Laser Pipe Cutting Machine is a healthy machine. Dirt, debris, and dust are major enemies of your pipe laser cutter machine. They not only affect the quality of your cuts but also reduce the lifespan of the machine. Therefore, it is crucial to clean your machine regularly to ensure its optimal performance and longevity. You can use a clean, dry cloth or a soft-bristled brush to remove any dirt or debris from the machine’s exterior. For the interior, you can use an air compressor to blow out any dust or debris. It is important to ensure that the machine is completely dry before using it again to avoid any electrical hazards.

Check The Bevel Laser Pipe Cutting Machine’s Parts Regularly

A Bevel Laser Pipe Cutting Machine has several parts that need to be checked regularly to ensure their proper functioning. Some of these parts include the cutting head, lenses, mirrors, and motors. By regularly checking these parts, you can identify any wear and tear and replace them before they cause any major damage to the machine. Keep in mind that it is important to keep an eye out for any signs of damage which may affect the precision of your cuts. If you notice any deviations in cut quality, it may be necessary to replace a part or get professional maintenance.

Ensure You Lubricate The Bevel Laser Pipe Cutting Machine Regularly

Lubrication is key to ensuring your Bevel Laser Pipe Cutting Machine runs smoothly and efficiently. Without proper lubrication, the machine’s moving parts can wear down and cause damage to the overall performance of the machine When lubricating your machine, it is important to use the recommended lubricant for each specific part. Over-lubricating or using the wrong type of lubricant can lead to build-up and clogging of the machine’s components, which can ultimately cause friction and damage.

Applications Of Bevel Laser Pipe Cutting Machine

Pre-Welding Beveling

Before metal welding, it is usually necessary to bevel the weld to improve the strength and quality of the welded joint. Bevel Laser Pipe Cutting Machine can be used to cut precise bevel shapes to meet different welding needs.

Steel Structure Processing

Bevel Laser Pipe Cutting Machine can be used to manufacture and process bevels in steel structures, such as steel bridges, steel buildings, steel girders and so on. Through bevel cutting, optimized joints and connections can be achieved to ensure the stability and safety of the structure.

Pipe Manufacturing

In the process of pipe manufacturing, bevel cutting is often required to realize the precise fit of pipe connections and joints. Bevel Laser Pipe Cutting Machine can be used to cut the bevel shape suitable for pipeline connection to improve the quality and efficiency of the pipeline.

Bevel Processing Before Solution Cladding

In solution cladding (Laser Cladding), often need to bevel the metal substrate cutting, in order to better integrate the laser cladding layer and the substrate. Bevel Laser Pipe Cutting Machine can be used to cut out the precise shape of the bevel to achieve high-quality solution cladding processing.

Automobile Manufacturing

Bevel Laser Pipe Cutting Machine bevel cutting has a wide range of applications in automobile manufacturing. It can be used to cut the bevel of automobile parts, such as body panels, suspension system parts and so on.

Shipbuilding

In shipbuilding, Bevel Laser Pipe Cutting Machine is often used to cut the bevel of the hull plate, in order to realize the connection of the hull plate and the joint structure of the bevel seal.

Our Certificate

Frequently Asked Questions

Q: What is a bevel laser pipe cutting machine?

Q: How does a laser beam cut metal pipes?

Q: What materials can be cut with a bevel laser pipe cutting machine?

Q: What factors determine the precision of a bevel cut?

Q: How is the bevel angle determined on a pipe cutting machine?

Q: Can a bevel laser pipe cutting machine cut internal surfaces of pipes?

Q: What is the typical lifespan of a laser cutting machine?

Q: How does a bevel laser pipe cutting machine compare to traditional cutting methods?

Q: Are there any limitations to the thickness of pipes that can be cut with a laser?

Q: What is the role of CNC in a bevel laser pipe cutting machine?

Q: How is the laser beam focused during the cutting process?

Q: What assist gases are used in bevel laser pipe cutting?

Q: How is the cutting speed of a bevel laser pipe cutting machine determined?

Q: What maintenance is required for a bevel laser pipe cutting machine?

Q: Can a bevel laser pipe cutting machine be integrated with other manufacturing systems?

Q: How does a bevel laser pipe cutting machine affect the environment?

Q: What training is required to operate a bevel laser pipe cutting machine?

Q: What are the benefits of using a bevel laser pipe cutting machine over manual methods?

As one of the leading bevel laser pipe cutting machine manufacturers in China, we warmly welcome you to buy durable bevel laser pipe cutting machine for sale here from our factory. All machines are with high quality and competitive price.